Skip to content

Highlights

- Combines two different thermoplastics into a single component

- Creates complex, multi-color, multi-material components

- Consolidates the number of parts

- Bonds are stronger than those from joining separate parts after molding

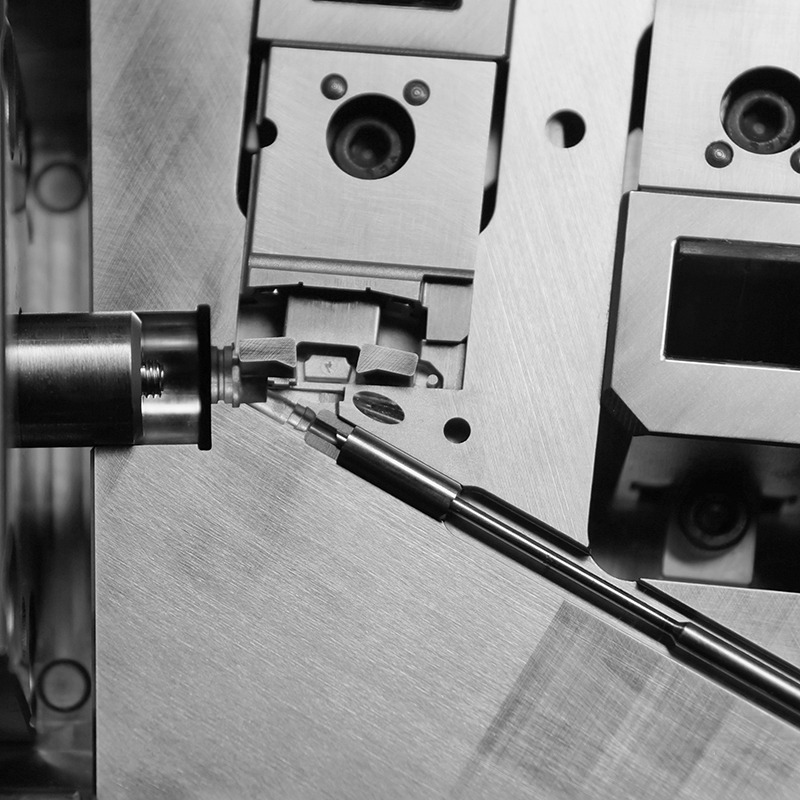

- Lower tolerances

- Improved repeatability and accuracy

- Uses turntable technology, index plate systems, and core-back technology as needed

- Expert, in-house mold building and decades of experience

- Also known as overmolding and double-shot molding

Examples of use

- Instrument handles with a hard core and softer, ergonomic outer material

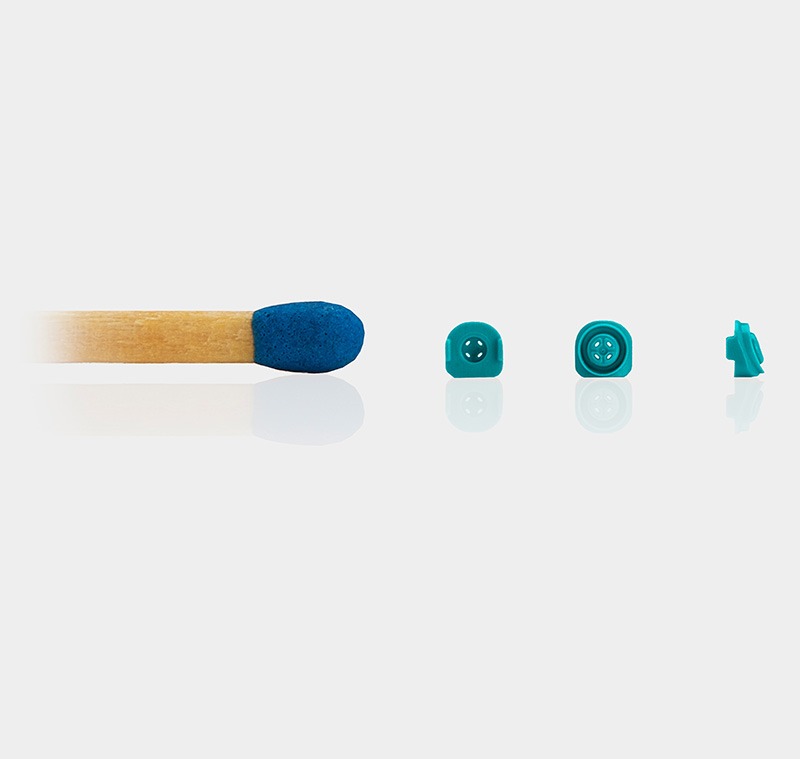

- Hearing aids

- Pacemakers and implantable cardioverter-defibrillators (ICD)

- Cardiovascular home monitoring devices

- Drug delivery

- Abutments for dental implants

Tegra Medical Molding Technologies