Types of products we manufacture

We make devices, assemblies, and components for a wide range of medical specialties. These include, but certainly are not limited to orthopaedics, cardiac care, women’s and men’s health, neurology, ophthalmology, otolaryngology, radiology, pain management and diabetes, among others.

The types of procedures in which our customers’ products are used include arthroscopy, endoscopy, joint reconstruction, robotic surgery, biopsies, drug delivery, and many more.

Specific product examples

We make a vast array of finished devices, assemblies, and complex components according to our OEM customers’ designs. The examples below are just a small subset of the sophisticated products we manufacture.

Soft tissue removal

Implants

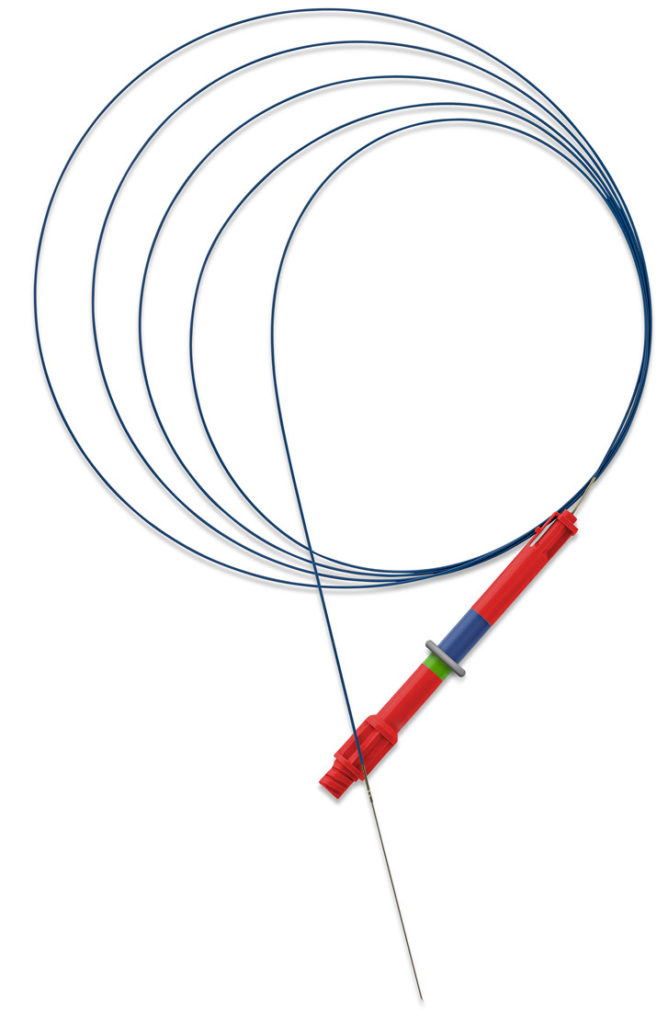

Needles, cannulae, and catheters

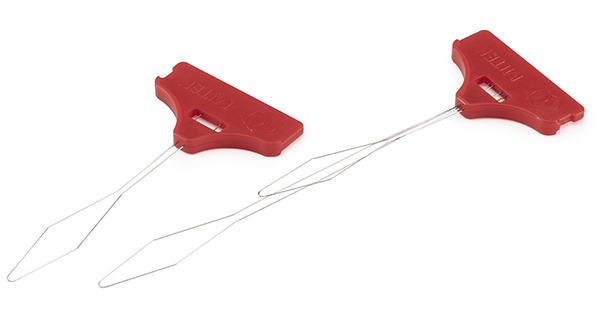

Suturing devices

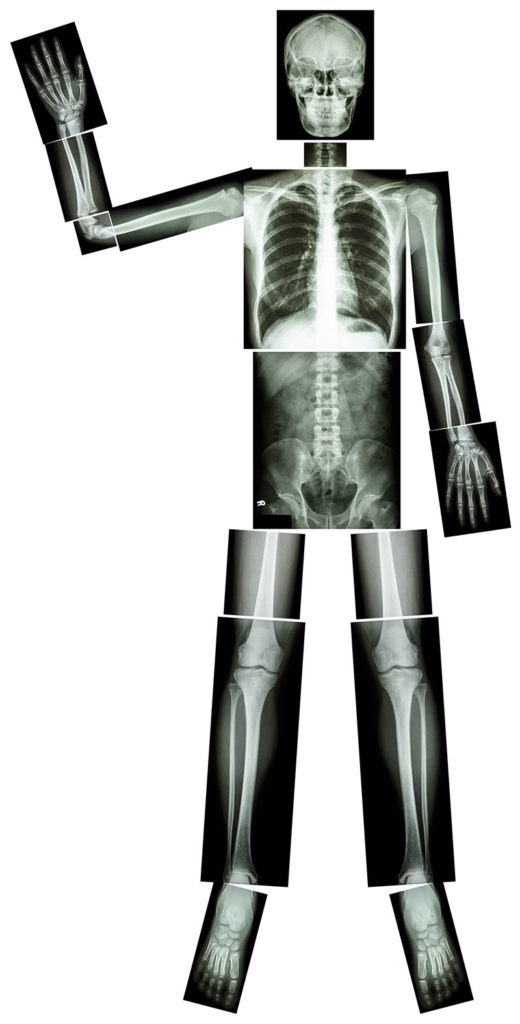

Devices from head to toe

The devices we manufacture range from head to toe and include these examples:

Head and neck

- Burr hole covers after brain surgery

- Tiny hearing aid components

- Handpieces for ENT surgery

- Incision template and devices for eye surgery

Spine

- Instruments for inserting cement into degenerated disks

- Cervical spine interbody fusion cages for treating scoliosis and spondylosis

- Retractors and spreaders for providing access during surgery

Arms and Shoulder

- Radiofrequency ablation (RF) energy devices used in shoulder surgery

- Shavers for soft tissue removal

- Suturing devices for rotator cuff surgery

Chest

- Vascular closure devices and catheters used in cardiac procedures

- Catheters for inserting and removing IVC filter to catch blood clots

- Regular and single-use endoscopes

- Components for pacemakers and defibrillators

- Biopsy devices for breast cancer

Hips

- Femoral head removers used in hip replacements

- Devices for treating enlarged prostates and removing uterine polyps

- Neurostimulators for bladder control

Legs, knees, and feet

- Navigation components for robotic assisted surgery

- Suturing instruments for meniscus repair

- Knee implants

- Femoral nail implants

- Devices for endoscopic treatment of gastrocnemius equinus to relieve foot disorders

- Instruments used for hammertoe surgery

Needles for all body parts

- Needles of all types including bone aspiration, tissue sampling, drug delivery, vertebroplasty, guidewire introducers, aspiration, huber, and epidural.