Skip to content

Highlights

- Insert molding

- Two-shot molding

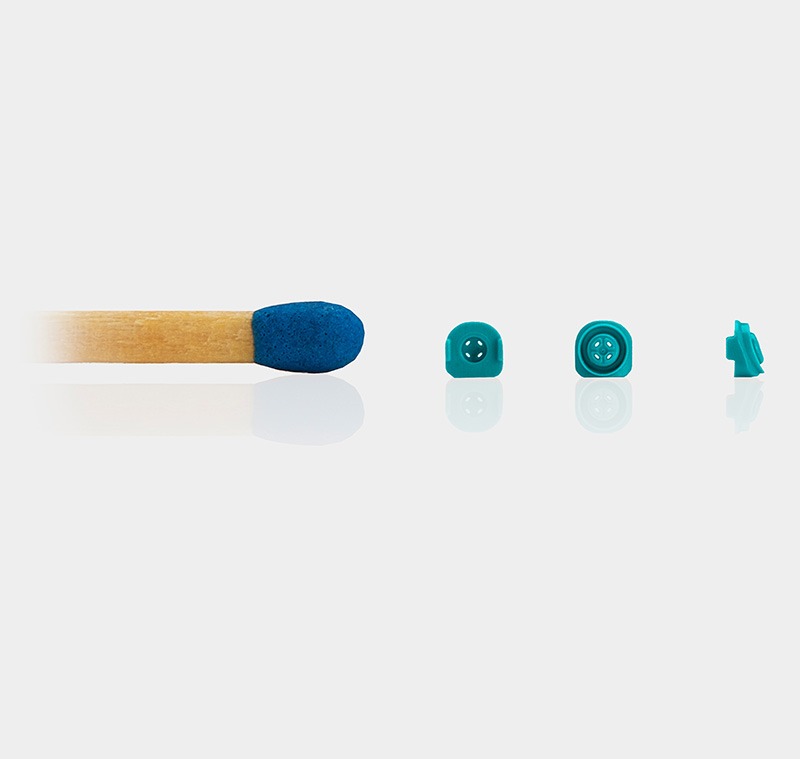

- Micro molding

- Hybrid components (plastic plus materials such as metal or ceramic)

- Thin-wall molding with wall thicknesses as thin as 0.006 in (0.15 mm)

- Tolerance requirements of ± 0.0004 in (0.01mm). Part weights between 0.0003 oz and 5.29 oz (0.01g and 150g)

- Work with over 500 different plastics

- ISO Class 7 (10,000) and ISO Class 8 (100,000) cleanrooms for controlled, particle-free production, assembly, and packaging

- Augmented by onsite pad printing and ultrasonic welding

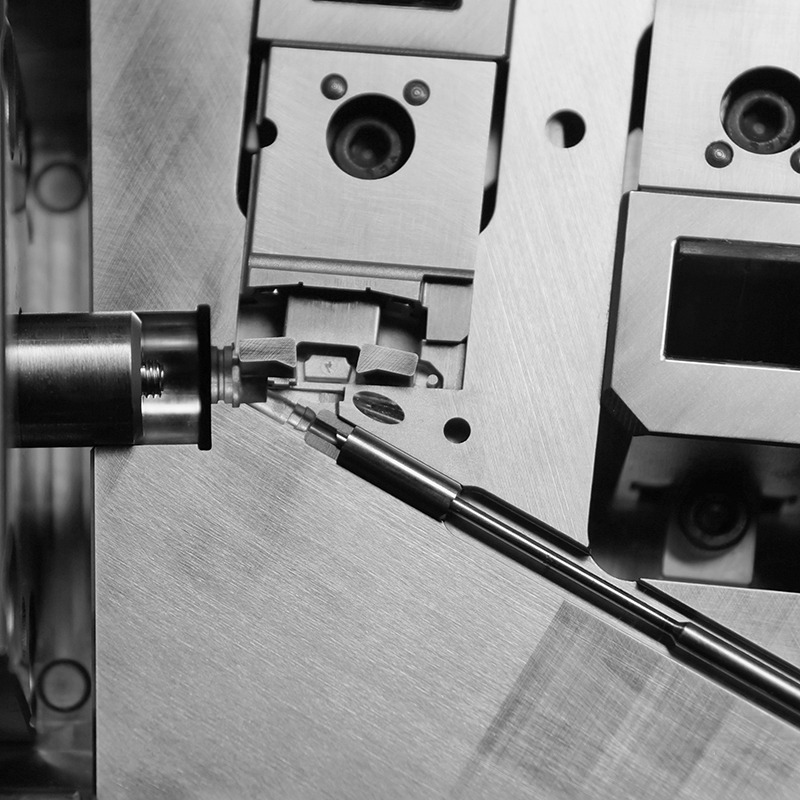

- Expert, in-house mold building and decades of experience

Examples of use

- Optical lenses in assemblies for sensor technology or optical measurement systems

- Insert-molded cannula and needles

- Luer taper hubs with ancillary attachments

- Defibrillators and pacemakers

- Neurostimulators

- Insert-molded stylets

- Insert-molded biopsy sets

- Injection-molded handle and trigger components

- Ultrasonic-welded wires, tubes, shafts, braided Nitinol

Tegra Medical Molding Technologies