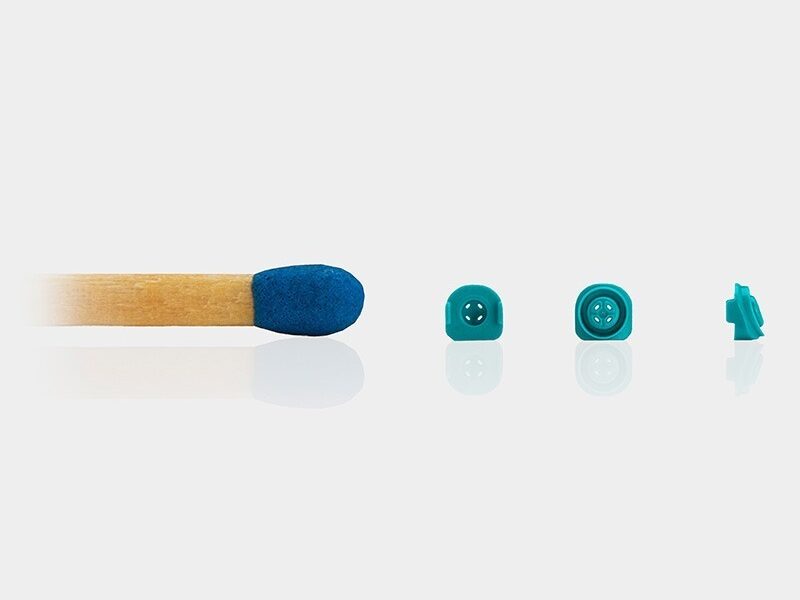

Micro Injection Molding

Our Micromolding capabilities are tailored to produce extremely small, intricate components with high levels of precision. We mold components with features as small as a few microns, essential for applications like minimally invasive devices and surgical instruments. Micromolding is perfect for producing very small, complex parts that demand superior detail, accuracy, and reliability, ensuring that even the smallest components perform reliably in critical applications.

Highlights

- Micro injection-molded parts in millions of variations

- Components weighing under 0.00004 oz (0.001g)

- Thin-wall molding with wall thicknesses as thin as 0.006 in (0.15 mm)

- Components molded consistently and with extreme precision

- Expert, in-house mold building and decades of experience

Examples of use

- Receiver protection for an in-ear hearing aid

- Incision template for exact trocar placement during eye surgery

- Overmolded tube for cardiovascular applications

- Disposable biopsy forceps

- Component for soft mist inhalers

- Drive components for drug delivery devices

- Grommets

Let’s Start the Conversation

Your next project begins with a conversation. Reach out to us today and let’s discuss your needs.