Manufacturing has evolved far beyond its labor-intensive origins. As the medical device industry demands ever-greater precision, automation has become essential for delivering high-quality, repeatable production while reducing reliance on manual labor.

Manufacturing Automation in Action: Real-World Applications

Automation transforms manufacturing across key production processes by reducing manual intervention, improving quality control, and accelerating production.

By integrating robotics, AI-driven vision systems, and data-driven automation, manufacturers can streamline operations while minimizing errors and waste. Applications include:

- Raw Material Handling. Automated systems improve material movement, reducing waste and enhancing efficiency.

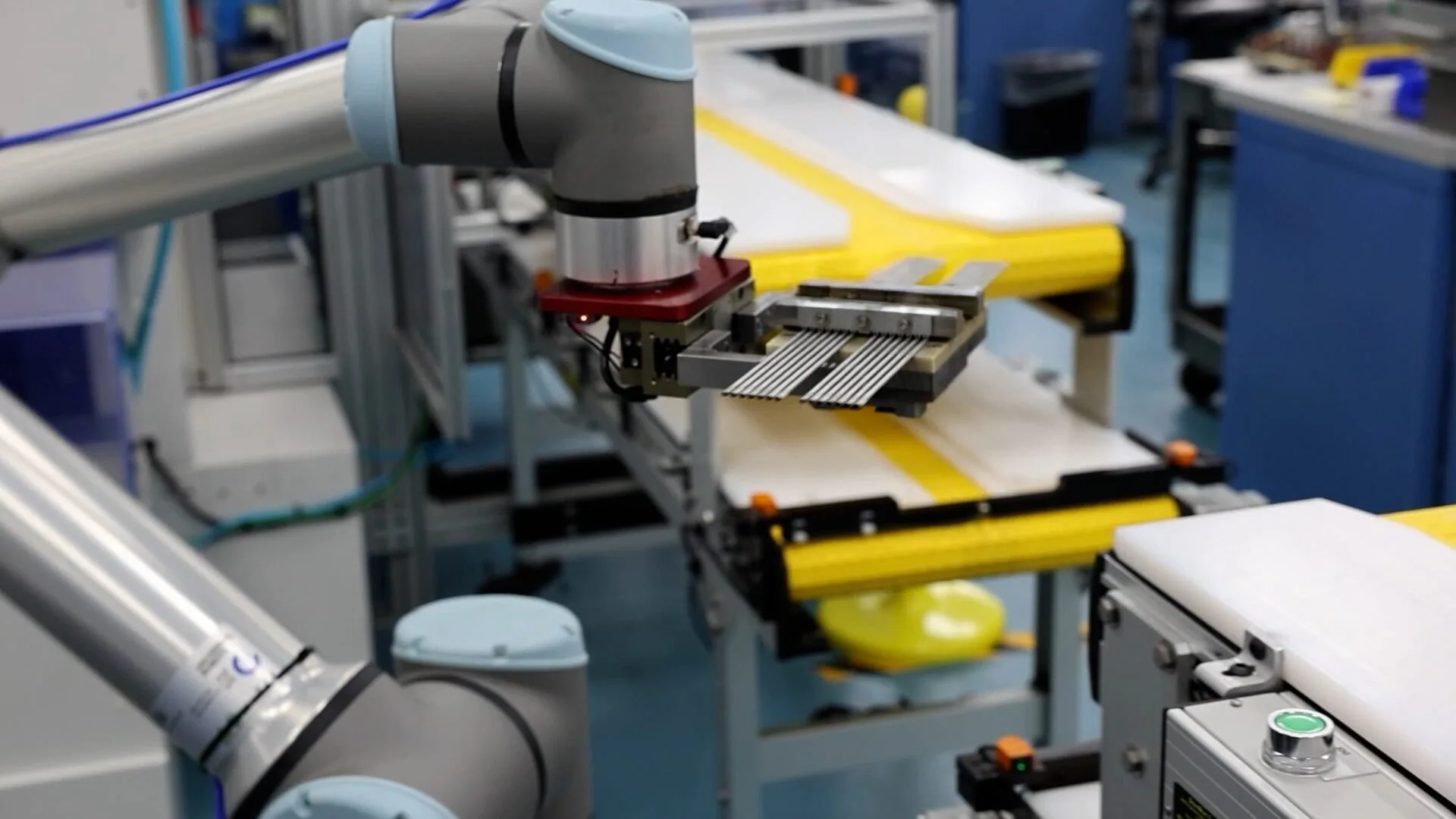

- Robotic Assembly. High-precision robotic systems ensure accurate component placement, minimizing human error.

- Automated Inspection & Vision Systems. AI-driven inspections enhance quality control, detecting inconsistencies with greater accuracy than manual checks.

- Automated Parts Loading and Unloading. Automation speeds up production while reducing manual handling risks.

- Data-Driven Process Automation. Smart technologies and software continuously monitor and optimize production workflows.

Benefits of Manufacturing Automation

Automation can help OEMs meet growing industry demands and stay competitive. Here are some key advantages:

- Improved Process Quality and Consistency. Automated systems ensure repeatability, reducing or eliminating human adjustments by integrating machine vision feedback, sensors, and inline gauging to verify part placement, straightness, and quality.

- Reduced Variation. Automation handles laser focusing and component fixturing, minimizing inconsistencies caused by tooling wear.

- Increased Throughput and Reduced Cycle Time. Concurrent operations, such as part retrieval, welding, and gauging, accelerating production.

- Cost Efficiency. Automation reduces labor costs and optimizes resource allocation, allowing skilled employees to focus on innovation and process optimization.

- Enhanced Quality Control. AI-driven inspection and automated output segregation improve product consistency and prevent lot-mixing errors.

- Safer Work Environments. Robots handle hazardous or repetitive tasks, reducing workplace risks and improving safety.

- Optimized Space Utilization. A single automated system delivers the output of 3–4 manual systems, consolidating processes and reducing manufacturing footprint.

- Talent Attraction and Retention. Companies investing in automation position themselves as industry leaders, attracting skilled professionals eager to work with cutting-edge technology

How Tegra Medical Can Help You Automate

Tegra Medical’s parent company, SFS, provides custom automation solutions tailored to medical device manufacturing to help OEMs meet stringent quality and regulatory requirements.

Based at SFS HQ in Heerbrugg, Switzerland, the SFS Technical Service group supports its subsidiaries with extensive experience in high-volume automation. That means Tegra Medical can integrate multiple core competencies into seamless automated workflows that include cold forging and forming machines, machining centers, test benches, sorting machines, welding machines, coating lines, high-end cleaning machines, and multi-cell assembly lines. By leveraging Tegra Medical’s deep expertise, we help medical device OEMs automate critical processes—from raw material handling to final inspection.

The Automation Edge

Manufacturers that embrace automation gain a significant competitive edge. By optimizing production, improving quality, and addressing workforce challenges, automation ensures that medical device OEMs can bring safe, effective products to market efficiently. With cutting-edge automation solutions, Tegra Medical continues to be a trusted partner for medical device manufacturers worldwide.

Contact us today to find out if it makes sense to automate your device production.