Tegra Medical’s Capabilities Go Beyond Metals

Many of Tegra Medical’s customers are aware of our expertise in metal manufacturing but may not realize that we’re equally proficient in the realm of injection molding.

Injection molding is a manufacturing process that produces high-precision components by injecting molten medical-grade plastics into a mold. This process is widely used in the medical device industry for its ability to create intricate designs, ensure consistent quality, and meet stringent regulatory requirements.

Tegra Medical’s Injection Molding Expertise

Tegra Medical can handle the full range of injection molding capabilities, which include:

- Insert Molding. This approach involves placing a prefabricated component, such as a metal insert or electronic part, into the mold before injecting plastic around it. It creates a single, integrated part, which is good for applications requiring durable connections or embedded features.

- 2K Molding (Two-Shot Molding). This technique combines two different materials or colors into one component by injecting them sequentially into a single mold. It’s ideal for creating parts with soft-touch surfaces or enhanced functionality.

- Overmolding. This method is similar to 2K molding, but instead of two materials being injected into the same mold, an additional layer of plastic is molded over a pre-existing part (which could be either metal or plastic). It’s used to enhance grip, insulation or aesthetics.

- Micromolding. A specialized form of injection molding for producing extremely small, intricate parts, often with tight tolerances, micromolding is essential for creating components for minimally invasive devices or precision surgical tools.

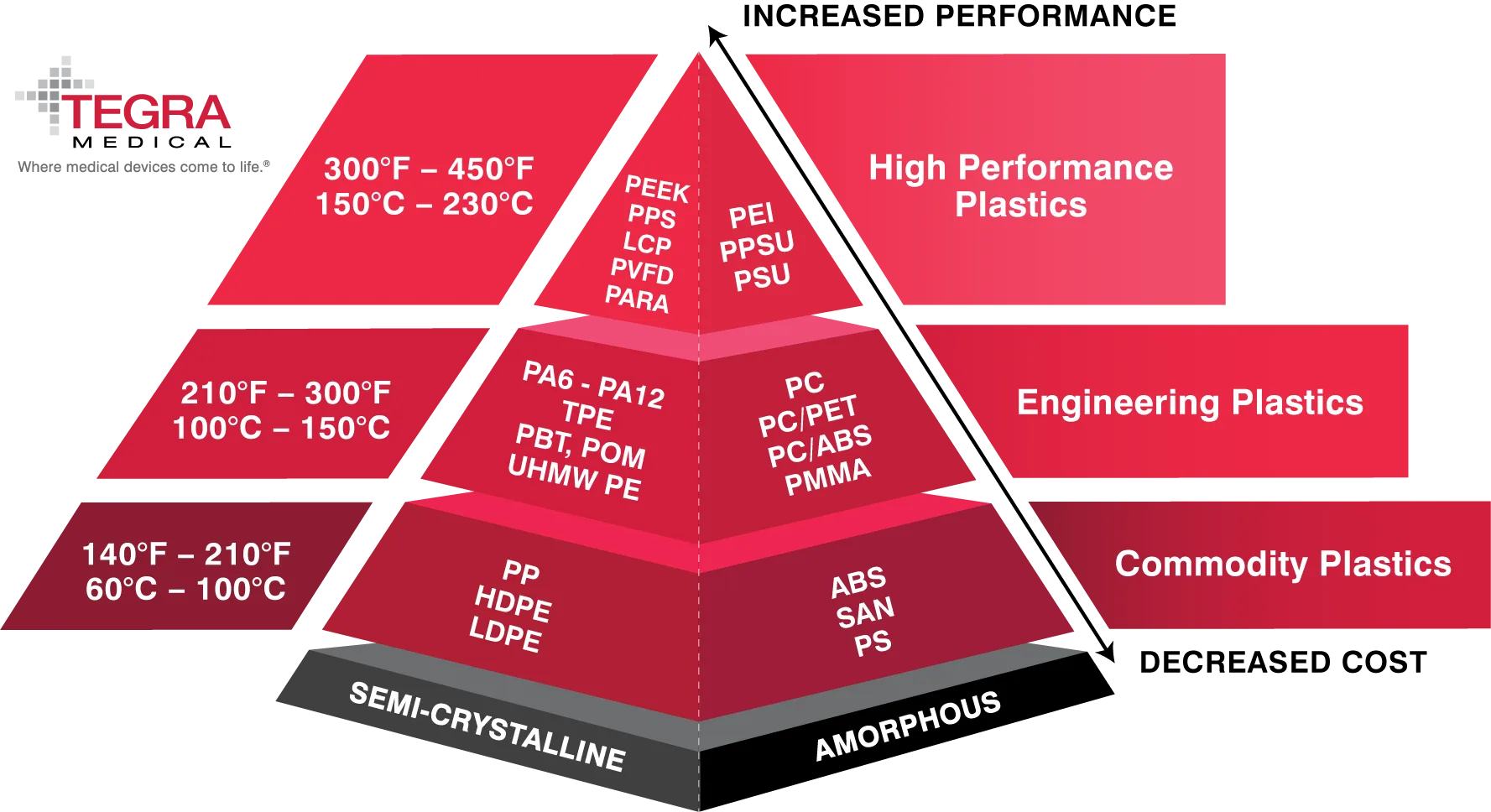

We work with commodity plastics for general applications; engineering plastics for devices where increased thermal and mechanical capabilities are important; and high-performance plastics when biocompatibility, strength, and meeting FDA and ISO 13485 standards are essential.

Alternate Processes: How Injection Molding Excels

In contrast to injection molding in medical device manufacturing, OEMs might turn to alternative processes such as compression molding extrusion molding, thermoforming, casting or 3D printing. However, most of these alternatives are less efficient in terms of speed, cost or precision compared to injection molding.

Injection molding is favored for its ability to produce high-precision, complex parts quickly and cost-effectively in large quantities. For high-volume production with stringent requirements, it’s hard to match injection molding’s efficiency.

Why Partner With a Company That Can Manufacture Both Metals and Plastics?

Since Tegra Medical can manufacture both metals and plastics, we can offer several key benefits to our customers:

- Comprehensive Solutions. We can handle complex projects that require both metallic and plastic components, streamlining the manufacturing process by serving as a one-stop shop. This simplifies your supply chain.

- Integrated Design and Assembly. Our expertise in both materials enables seamless integration of parts, improving device performance and reducing the risk of compatibility issues.

- Cost and Time Efficiency. Consolidating production under one roof minimizes the need for multiple manufacturing steps, which reduces lead times, shipping costs and administrative overhead.

- Innovative Opportunities. Dual material expertise allows for innovative designs, such as hybrid components that leverage the strengths of both metals (durability) and plastics (lightweight and versatile). Combining parts into one component can also contribute to cost savings.

- Simplified Regulatory Compliance. A single manufacturer familiar with the regulatory standards for both materials ensures consistency in meeting stringent medical device requirements for biocompatibility and safety. Additionally, the controlled environment of cleanrooms during molding minimizes contamination risks.

- Scalability. Companies with this capability can support various production scales, from prototyping to high-volume manufacturing, across a range of device applications.

Tegra Medical operates multiple facilities specializing in injection molding for medical devices in the United States, Europe and Asia. The facilities are equipped with advanced technologies to produce complex components and finished devices, ensuring high-quality standards in medical device manufacturing. By partnering with us, you gain a trusted ally capable of delivering comprehensive solutions for your most complex projects.

Let’s talk about how we can help you with your next injection molding project! Contact us.