Creative solutions for drug delivery

Drug delivery devices need to be simple for patients and practitioners to use, but manufacturing them can be complex.

Fortunately, manufacturing complex devices and components is Tegra Medical’s specialty and takes advantage of our expertise in combining non-traditional and common manufacturing technologies to find creative solutions for efficient manufacturing.

Drug delivery device examples

Some of the devices and components we manufacture for drug delivery include:

- Springs, needles, and other components for injection systems, pumps, and patches

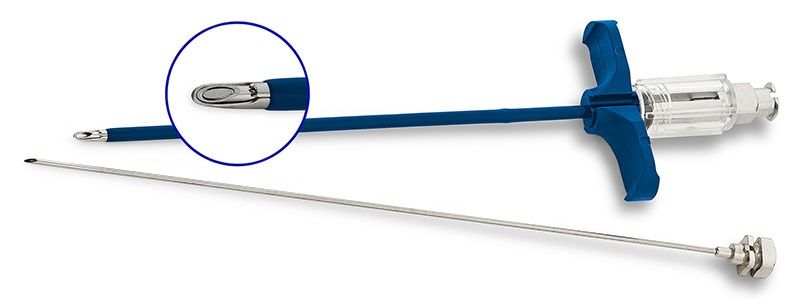

- Huber needles for puncturing implanted drug-delivery devices, such as ports and pumps

- Insert molded needles such as epidural and custom

- Injection-molded housings for devices used to inject medicine

- Implantable ports

- Brachytherapy seeds

- Catheter guidewires

- Inhaler components

- And more

Product development for drug delivery devices

Whether you need manufacturing for a new drug delivery device or are seeking a new manufacturer for an existing product our GENESIS Tech Center® engineers will team up with your engineers to help refine your design and find the most efficient way to make it.

Our deep experience with both metal and plastic means we’re positioned to meet your stringent requirements for drug delivery components, assemblies and finished devices.

Manufacturing expertise

The capabilities we offer to manufacture drug delivery devices include:

- Injection molding, including micro-, two-shot, and insert molding

- CNC machining

- Needle grinding

- Stamping

- Wire forming

- Cold forming

- Surface treatments

- Full production, cleanroom assembly, packaging, and sterilization

Get sharp. Stay sharp.

Sharpness is critical for many drug delivery devices. Our ability to make and keep sharp edges is practically legendary.

We are a true end-to-end manufacturer, which means we handle every process when making your product. So when we’re adding a molded plastic handle, doing the finishing processes, and packaging it we make sure the pointy “business end” stays just as sharp when we’re done.