Harnessing technology for medical device manufacturing

Sometimes the best way to make a particular device is by combining non-traditional and common manufacturing technologies. But this can be too much of a challenge for some suppliers.

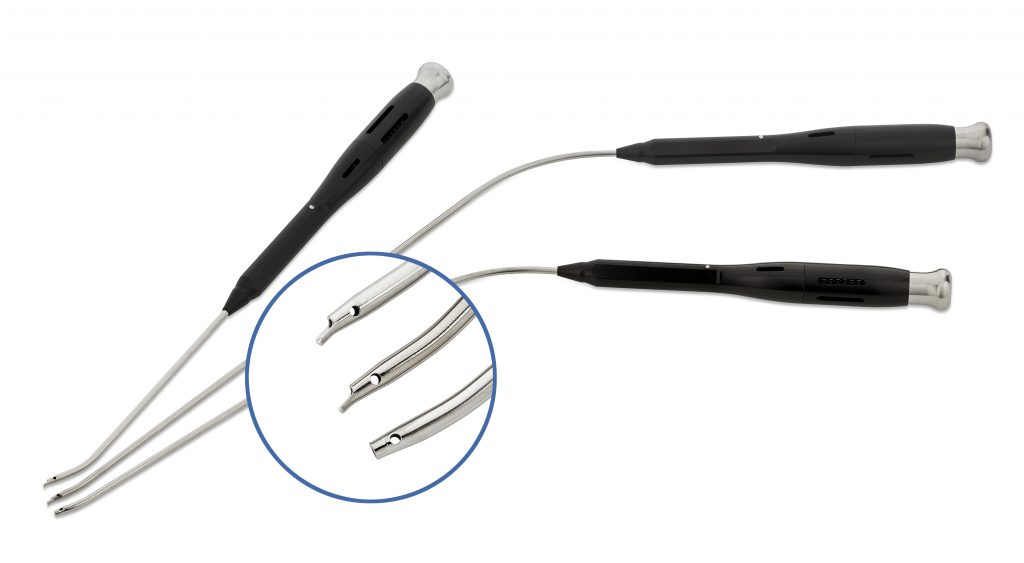

For example, we combine laser cutting with CNC grinding and metal forming to make these hand pieces for a surgical device used in head and neck procedures.

We like the hard stuff and thrive on challenges that create knots in the stomachs of other manufacturers.

Precise anatomical bends

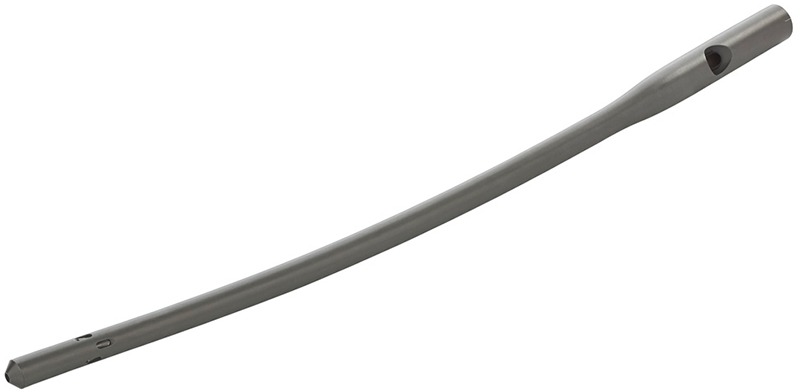

Some medical devices must have precise anatomical bends. The metal or plastic must be manufactured to mimic the exact curve of a human body part so it can serve its purpose.

This femur implant device might look simple, but it’s actually highly precise — much to the appreciation of the patient whose broken femur will be repaired and the surgeon fastening the implant into place.

The black-handled devices above include precise bends to assist in accessing hard-to-reach anatomy.

Get sharp. Stay sharp.

Our ability to make and keep sharp edges is practically legendary.

We are a true end-to-end manufacturer, which means we handle every process when making your product. So when we’re adding a molded plastic handle, doing the finishing processes, and packaging it we make sure the pointy “business end” stays just as sharp when we’re done.